Pololu High-Power Motor Driver 36v20 CS

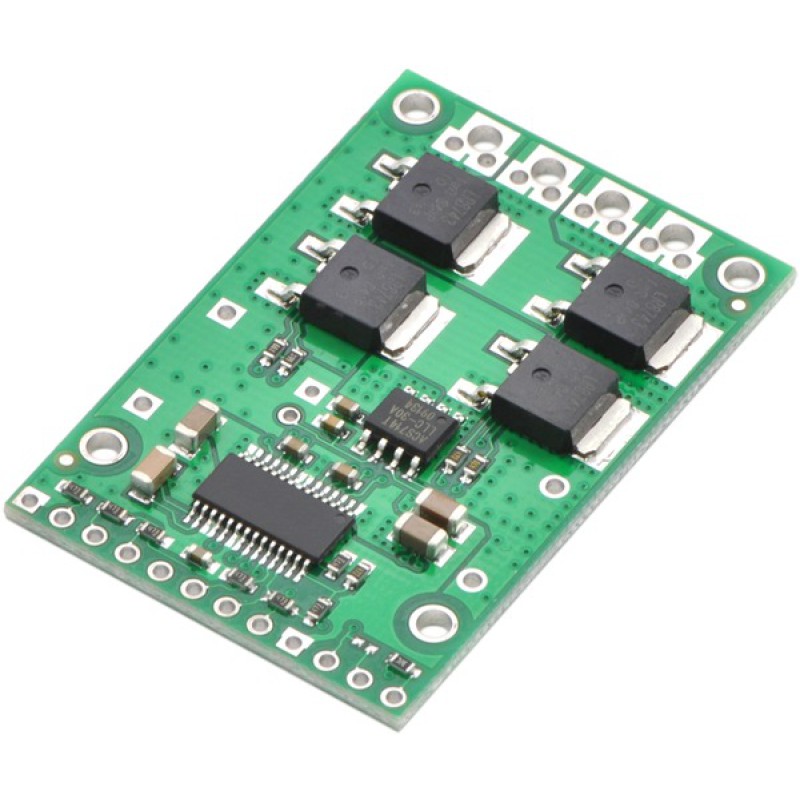

The Pololu high-power motor driver is a discrete MOSFET H-bridge designed to drive large

DC brushed motors. The H-bridge is made up of one N-channel MOSFET per leg, and most of the board’s performance is

determined by these MOSFETs (the rest of the board contains the circuitry to take user

inputs and control the MOSFETs). The MOSFET datasheet is available under the “Resources” tab.

The board has an absolute maximum voltage rating of 50V; higher voltages can permanently destroy the motor driver.

Under normal operating conditions, ripple voltage on the supply line can raise the maximum

voltage to more than the average or intended voltage, so a safe maximum voltage is approximately 44V.

The versatility of this driver makes it suitable for a large range of currents and voltages:

it can deliver up to 20A of continuous current with a board size of only 1.8" by 1.2" and no required heat sink.

With the addition of a heat sink, it can drive a motor with up to about 32A of continuous current.

The module offers a simple interface that requires as few as two I/O lines

while allowing for both sign-magnitude and locked-antiphase operation,

and an optional third control input unique to this board allows for coasting.

This board also features a current-sensing circuit that measures

bidirectional motor current with a magnitude up to 30A and outputs an analog voltage.

Integrated detection of various short-circuit conditions protects against

common causes of catastrophic failure; however, please note that the board does not include reverse power

protection or any over-current or over-temperature protection.

We recommend you use the integrated current sensor to keep the

driver from delivering more current than it can safely handle.

Using the Motor Driver

Connections

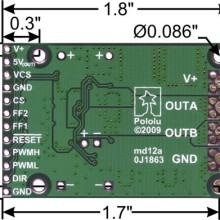

The motor and motor power connections are on one side of the board, and the control connections

(5V logic) are on the other side.

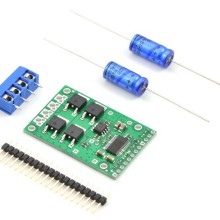

The motor supply should be capable of delivering the high current the motor will require,

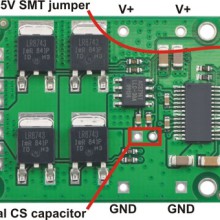

and a large capacitor should be installed between V+ and ground close to the motor driver to decrease

electrical noise. Two axial capacitors are included and one or both can be installed by

soldering them into the V+ and GND pins (labeled '+' and '-' on the bottom silkscreen) along the long edges

of the board. Such installations are compact but might limit heat sinking options; also,

depending on the power supply quality and motor characteristics, a larger capacitor might be required.

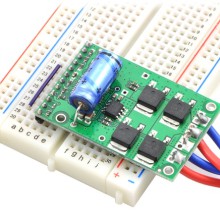

There are two options for connecting to the high-power signals (V+, OUTA, OUTB, GND):

large holes on 0.2" centers, which are compatible with the included terminal blocks,

and pairs of 0.1"-spaced holes that can be used with perfboards,

breadboards, and 0.1" connectors.

Warning: Take proper safety precautions when using high-power electronics.

Make sure you know what you are doing when using high voltages or currents! During normal operation,

this product can get hot enough to burn you.

Take care when handling this product or other components connected to it.

The logic connections are designed to interface with 5V systems (5.5V max);

the minimum high input signal threshold is 3.5V, so we do not recommend

connecting this device directly to a 3.3V controller. In a typical configuration,

only PWMH and DIR are required, but PWML can be used to enable coasting if both PWML and

PWMH are driven low. PWML is pulled high and PWMH is pulled low internally.

The two fault flag pins (FF1 and FF2) can be monitored to detect problems

(see the Fault Flag Table below for more details). The RESET pin, when held low,

puts the driver into a low-power sleep mode and clears any latched fault flags.

The V+ pin on the logic side of the board gives you access to monitor the motor’s power supply or pass

it on to low-current devices (it should not be used for high current).

The board also provides a regulated 5V pin which can provide a few milliamps

(this is typically insufficient for a whole controlcircuit but can be useful as a reference or for very low-power microcontrollers).

This pin can be shorted to VCS to power the current sensor, or VCS can be supplied with 5V externally.

If the 5V output pin is used to power VCS, it should not be used for any other purpose

as the current sensor will draw close to the limit of the current the 5V pin can supply.

When the current sensor is powered by applying 5V to VCS, the CS pin outputs

66mV/A for currents between -30 and 30A centered at 2.5V

מידות

| Size: | 1.8" x 1.2" |

|---|---|

| Weight: | 7 g1 |

מאפיינים כלליים

| Motor channels: | 1 |

|---|---|

| Minimum operating voltage: | 5.5 V |

| Maximum operating voltage: | 50 V |

| Continuous output current per channel: | 20 A2 |

| Current sense: | 0.066 V/A3 |

| Maximum PWM frequency: | 40 kHz4 |

| Maximum logic voltage: | 5.5 V |

| MOSFET on-resistance (max per leg): | 4.8 mΩ |

| Reverse voltage protection?: | N |