Wheel Encoder Set

This is a set using a pair of 42x19mm wheels, a pair of extended brackets, and two matching wheel encoders.

This quadrature encoder board is designed to hold two infrared reflectance sensors

inside the hub of the 42x19mm wheel and measure the movement of the twelve teeth along the wheel?s rim.

The two sensors are spaced to provide waveforms approximately 90 degrees out of phase,

allowing the direction of rotation to be determined and providing four counts per tooth for a resolution of 48 counts per wheel rotation.

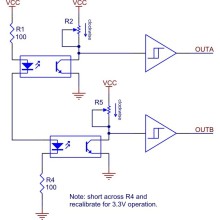

Each analog sensor signal is fed to a comparator with hysteresis to provide glitch-free digital outputs.

The compact layout of the board fits all of the components within the envelope of the hub and tire,

allowing the board to be mounted between the motor and a chassis.

The encoder is calibrated for operation from 4.5V to 5.5V, but it can be recalibrated for operation at 3.3V

(see photo to the right).

The two outputs of the encoder are digital outputs that can be connected directly to digital input pins on most microcontrollers

(inputs that can generate interrupts on change are recommended).

With 48 state changes per revolution of the 42mm wheel, a speed of 1m/s

(a bit over 3 feet per second) generates approximately 360 state changes per second.

With two encoders used simultaneously, as is the case for most differential-drive robots,

the encoders will require attention almost every millisecond.

Decoding the encoder outputs should only take a few percent of the processing power of

a microcontroller such as the Atmel ATMega168.

מאפיינים:

- 4.5V - 5.5V operating voltage

- 2 digital outputs

- 14mA consumption at 5V

- 48 counts per revolution (linear resolution just under 3mm)

- 2A continuous paralleled output current

- 100kHz maximum PWM frequency

- 2.7-5.5VDC logic voltage

מידות:

1.6g

תיעוד: